Directional Drilling Services

Proven

Safety Systems

Focused on Efficiency and Integrity

Where experience counts

DRC Drilling Pty Ltd has quickly established itself as the leading provider of Directional Drilling services for both surface and underground projects throughout Australia.

We have a pedigree that is second to none in the drilling industry. Our experience and knowledge in the contract drilling industry stretches back over 40 years and the vast wealth of expertise gathered during this time provides our clients with the security of knowing they will get what they want, when they want it.

We have met and exceeded our clients’ expectations with the introduction of leading-edge directional drilling technology, proven safety systems, efficiency and integrity.

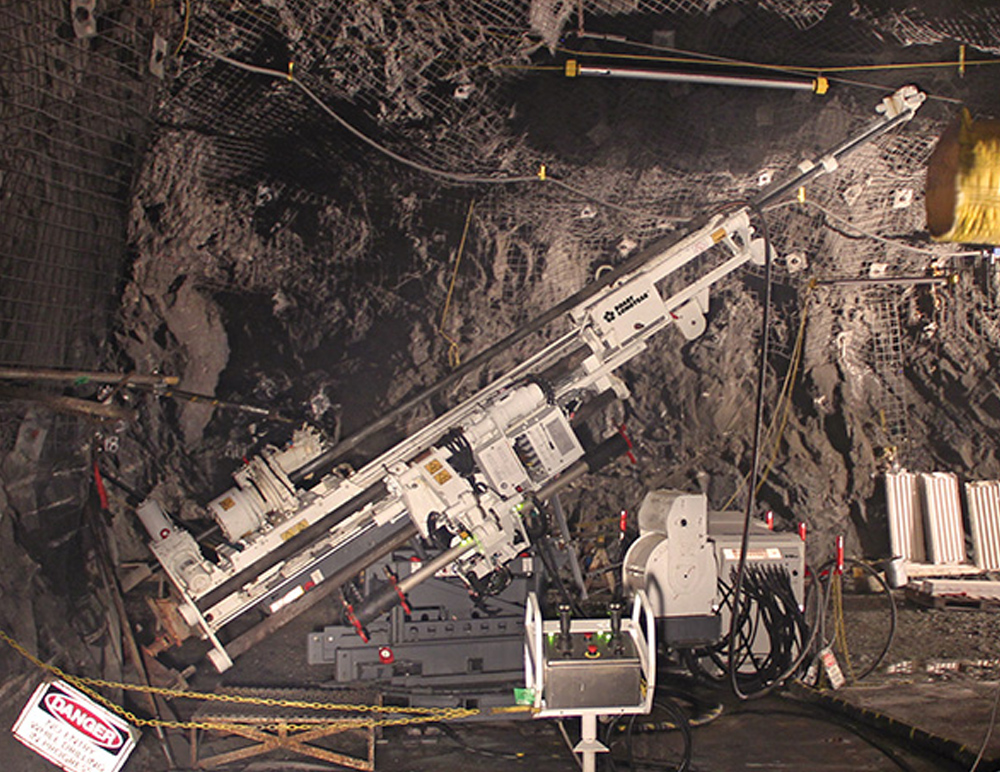

Underground Drilling

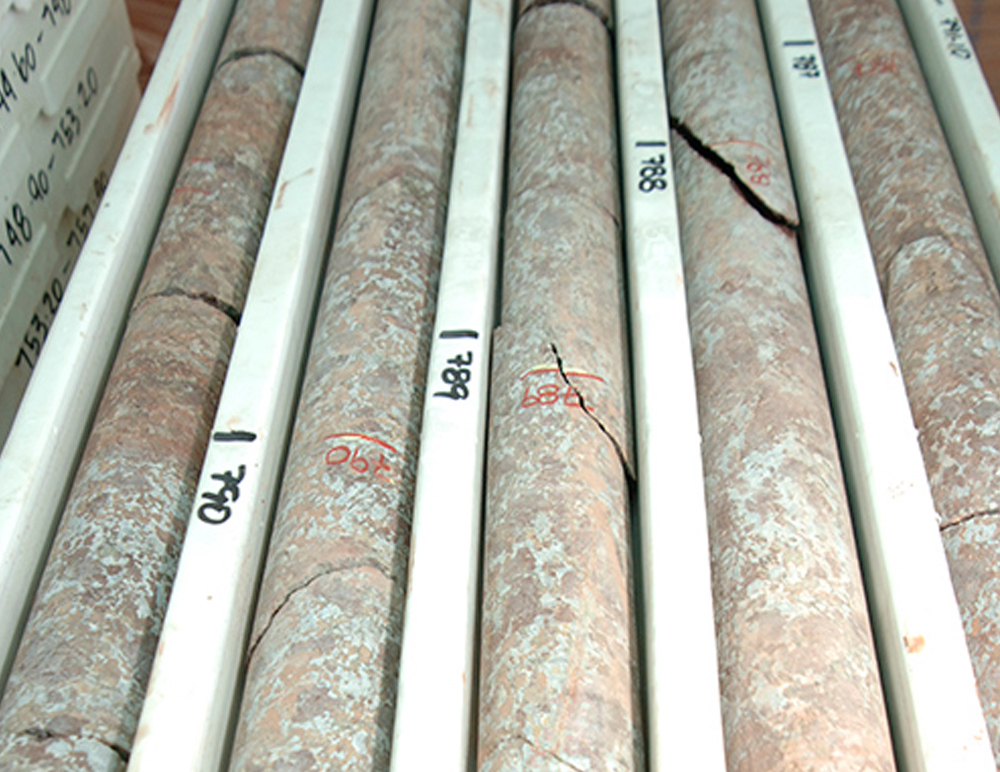

DRC Drilling currently operates a fleet of 13 underground drills consisting of ten Boart Longyear LM1300’s and three Boart Longyear LM700’s equipped with LM90 Power Packs.

We have also recently acquired an LM110 Power Pack fitted with the LM Drill Control Interface (DCi) for enhanced safety, hands-free making or breaking of joints and semi-autonomous drilling.

Featured services

- Deep Hole

- NQ to 1400 metres

- HQ to 700 metres

- LTK60 360° Infill Drilling

- Wedging – Directional

- Navi – Hole Steering

- Full Hole/Part Hole Grouting

- Pressure Grouting

- Hydro Fracturing

Surface Mineral Exploration Drilling

DRC Drilling’s surface drill fleet consists of seven late model Sandvik multi purpose drill rigs. DRC Drilling’s rigs have the capacity to drill at a range of depths from shallow to deep directional 3,174 metre holes, utilising various drilling methods.

- Diamond Drilling

- Reverse Circulation (RC)

- Air Core

- Geotechnical

- Rotary Mud

Rig Specifications

After years in the industry, we know that to provide quality drilling solutions to our clients, you need not only the best people who take pride in what they do but also the best gear. Our investment in sourcing from worlds best suppliers means our customers get what they expect. Every time. Whether it is Boart Longyear or Sandvik drill rigs, Mercedes Benz support trucks or Atlas Copco compressors, we don’t compromise when choosing plant and equipment for your drilling program.

Our support equipment is just as important in ensuring the whole project is delivered smoothly. Komatsu Integrated Tool carriers, mobile camps/offices, Explorex caravans, Almet Masters rod sloops and Briteforce lighting towers all combine to create the complete package. This means you can focus on what you do best.

Our people make it happen

Safety

first

Environmental objectives and targets are set and reviewed within the company, which has key environmental management and performance indicators against its operations.

All of our Drillers are Certificate 3 qualified and our Driller’s Assistants hold an inhouse Certificate 2 qualifications or higher.

We cater to the growing demand for trained, drilling specific personnel.